Lauda – Process Thermostats – Integral T / XT New Generation

The New Integral Process Thermostats Totally Integral

The new generation of Integral process thermostats for professional external temperature control, Integral T from -30 to 150 °C; Integral XT from -90 to 320 °C.

Integral T New Generation

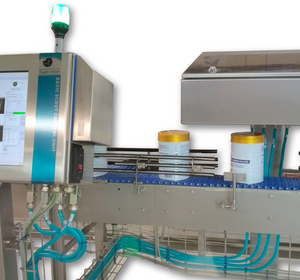

The new LAUDA Integral T process thermostats ensure efficient control of external temperature control processes in the temperature range from -30 to 150 °C. The units enable rapid temperature changes due to adapted heating and cooling capacities with small internal volumes. Due to the open hydraulic system, the unit vents quickly and without functional restrictions. This makes it ideal for temperature control processes with frequent consumer or specimen changes. A reliable, powerful submersible pump and the internal bypass for pressure limitation are standard features of the Integral T. The modular interface concept is now also implemented in the Integral T and ensures maximum networking of the user processes.

Integral XT New Generation

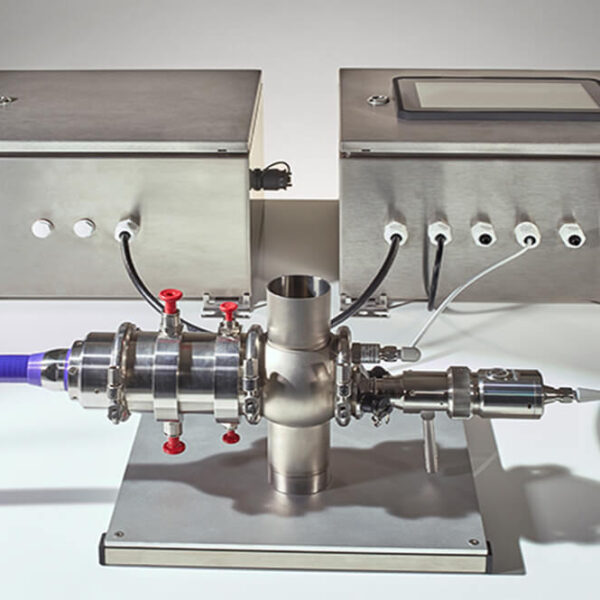

The powerful Integral XT process thermostats use the flow principle with cold oil superimposition. It allows users to use a wide temperature range with a temperature control medium. The electronically controlled, magnetically coupled eight-stage LAUDA Variopump allows the optimum thermal connection of the volume flow both for pressure-sensitive consumers and for applications with high hydraulic resistance. The modular interface concept ensures maximum networking of the user processes.

Technical Specifications

| Integral T | |||||||

| Integral IN 130 T | Integral IN 230 T | Integral IN 230 TW | Integral IN 530 T | Integral IN 530 TW | Integral IN 1030 T | Integral IN 1330 TW | |

| Working temperature range | -30 – 120 °C | -30 – 120 °C | -30 – 120 °C | -30 – 120 °C | -30 – 120 °C | -30 -150 °C | -30 – 150 °C |

| Filling volume range | 3.6 – 8.7 L | 3.6 – 8.7 L | 3.6 – 8.7 L | 7.2 – 20.5 L | 7.2 – 20.5 L | 9.7 – 25.5 L | 9.7 – 25.5 L |

| Temperature stability | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.1 ±K | 0.1 ±K |

| Pump pressure max. | 3.5 bar | 3.5 bar | 3.5 bar | 3.5 bar | 3.5 bar | 5.5 bar | 5.5 bar |

| Pump flow max. (pressure) | 40 L/min | 40 L/min | 40 L/min | 40 L/min | 40 L/min | 60 L/min | 60 L/min |

Integral XT

| Integral XT | |||||||||||

| Integral IN 150 XT | Integral IN 550 XT | Integral IN 550 XTW | Integral IN 750 XT | Integral IN 250 XTW | Integral IN 950 XTW | Integral IN 280 XT | Integral IN 280 XTW | Integral IN 1590 XTW | Integral IN 590 XTW | Integral IN 1850 XTW | |

| Working temperature range | -45 – 220°C | -50 – 220 °C | -50 – 220 °C | -45 – 220 °C | -45 – 220°C | -50 -220 °C | -80 -220 °C | -80 – 220 °C | -90 – 220 °C | -90 – 220 °C | -50 – 220 °C |

| Filling volume range | 2.5 – 8.7 L | 4.8 – 17.2 L | 4.8 – 17.2 L | 4.8 – 17.2 L | 2.5 – 8.7 L | 4.8 – 17.2 L | 4.8 – 17.2 L | 4.8 – 17.2 L | 10 – 30.6 L | 8.0 – 28.6 L | 8.0 – 28.6 L |

| Heater power | 3.5 kW | 8.0 kW | 8.0 kW | 8.0 kW | 3.5 kW | 8.0 kW | 4.0 kW | 4.0 kW | 12.0 kW | 8.0 kW | 16.0 kW |

| Cooling output at 20 °C measured with ethanol | 1.5 kW | 5.0 kW | 5.8 kW | 7.0 kW | 2.1 kW | 9.5 kW | 1.60 kW | 1.70 kW | 18.50 kW | 4.5 kW | 20.0 kW |

| Temperature stability | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K | 0.05 ±K |

| Pump pressure max. | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 3.1 bar | 6.0 bar |

| Pump flow max. (pressure) | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 65 L/min | 120 L/min |

Key Features

Integral T / XT New Generation

- Renowned quality – The Integral product line has proven itself in a wide variety of industries and applications for 20 years. Now we are taking process thermostats into the digital age – innovative, modern and with a large number of new functions.

- Maximum connectivity – Future-proof and Cloud-ready: Integral thermostats can be flexibly integrated in various communication scenarios thanks to the integrated web server, monitoring and control via PC or mobile devices and the modular interface concept.

- Compliant with the F-Gas Regulation – All Integral process thermostats of the new generation comply with the European F-Gas Regulation and are therefore ideally equipped for future use.

- Powerful and dynamic – Our integral process thermostats perform impressively in all areas of application with a cooling capacity of up to 20 kW, a heating output of up to 16 kW, a working temperature range from −90 to 320 °C and a flow rate up to 44 % higher.

- User-friendly operation – Softkey control directly on the device, remote control via touch display or mobile devices mean that it has never been easier to control your temperature control applications according to your requirements. The new Integral devices determine the optimum control parameters for the application at the touch of a button, and the temperature control liquid can be selected to ensure safe and optimum use of the liquid. The high-precision through-flow control unit extends your options and ensures absolute control over your test and production processes.

- Integrated bypass – More flexibility for your temperature control tasks. The standard integrated bypass allows pressure and flow optimization, thereby facilitating variable adaptation to a wide range of applications.

Integral T/XT

Integrated for the Future

Key Industries

- Agriculture

- Biopharmaceutical and Biotechnology

- Chemical

- Food & Beverage

- Medical

- Pharmaceutical