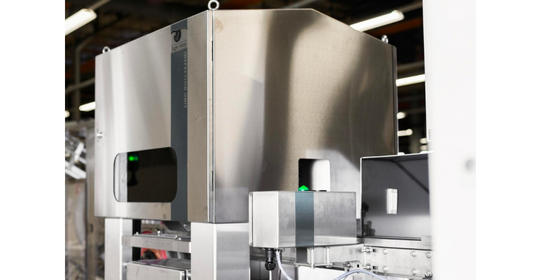

Eagle Vision – 360˚ Can Inspection System

The 360° Can Inspection module is a highly accurate Mix-Up & Integrity Detection system for cans. The system integrates critical functionalities including (Bar- & DMC- & QR-) Code reading and Color Artwork & Damages inspection in one “all-in-one” system.

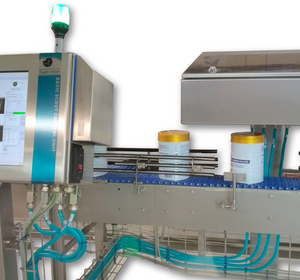

Extra relevant modules can be connected. For example Empty Can Inspection (inspects inside of can and the flange), Seam Inspection, and/or Cap Inspection.

The system is used by (Infant Formula) Can Fillers, Can Makers, and similar products with challanging reflective surfaces, such as Bottles, Jars and soup/sauce Cups.

Functionalities

- Barcode Reading (ladder + picket fence oriented)

- 2D Data Matrix Code Reading, including QR codes

- Decoration Inspection, including colour print quality, ghost prints (double prints), upside-down cans and damages

Options

- OCR Code Reading

- Label positioning

- Empty Can Inspection (inside + flange)

- Seam Inspection

- Cap Inspection

- Code Reading of batch/date codes

What Our 360 Can Inspection Can Benefit

- Automatic learning functionality

- Short changeover time using product library or MES input

- Compact footprint available

- No mechanical adjustments needed

- Proven standard system

- Random product orientation

- Simple installation to the line

- Stainless steel hygienic frame

- Network connection

- Remote access connection

- Storage of statistics and pictures

- Very operator friendly user interface

- Easy maintenance because of no moving parts

Key Industries

- Food & Beverage

- Pharmaceutical

- Machinery & Manufacturing