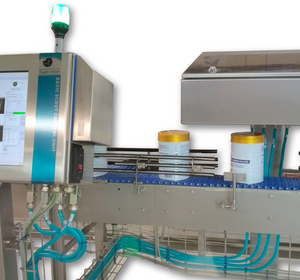

Eagle Vision – 360˚ Can Inspection System

The 360° Can Inspection module is a highly accurate Mix-Up & Integrity Detection system for cans. The system integrates critical functionalities including (Bar- & DMC- & QR-) Code reading and Color Artwork & Damages inspection in one “all-in-one” system.