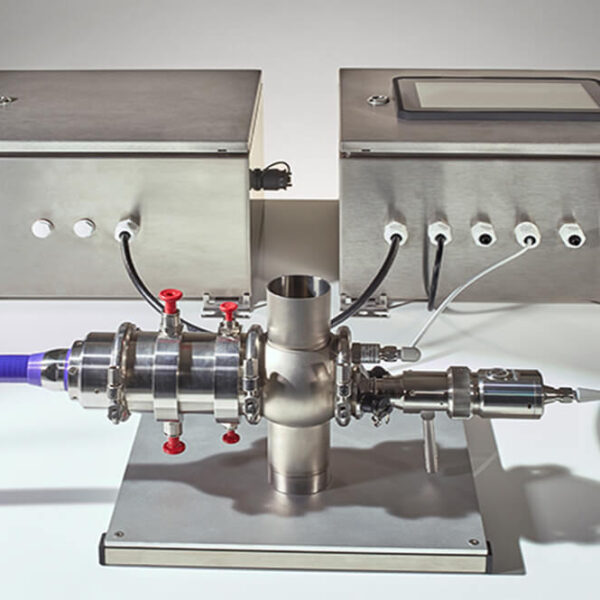

Eagle Vision – In Line Seam Inspection

The Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively.

The in-line Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively. Various can sizes and can shapes are inspected without any product handling. The inspection is available for high line speeds.

Lab measurements equipment are highly accurate, based on samples as a selection of the entire production. Due to that defective seams can be detected too late and inconsitantly.

Functionalities

- Seam Dents

- Droops/Vee

- Cut seam

- Knocked down flange

- Double seam

- Incomplete seam

- False seam

- Tight/loose seam

- Cut down seam

- Seam spinner/turned corner

Applications

- Automated vision inspection

- Can inspection

- Leak detection

- Seam inspection

Key Features

What You Can Benefit From Our in Line Seam Inspection System

- In-line inspection of Seam

- Inspects 100% of the produced cans

- Non-destructive

- No product handling needed

- High speed available (up to 90.0000 products per hour)

- Different can sizes and shapes, including round and rectangular cans

- Modular expandable with other inspection modules

- Network connection

- Remote connection

- Storage of statistics and pictures

- Short changeover time

- Simple installation to the line

- Stainless steel hygienic frame

- Very operator friendly user interface

- Easy maintenance because of no moving parts

Key Industries

- Food & Beverage

- Machinery & Manufacturing

- Education & Academics